Product description

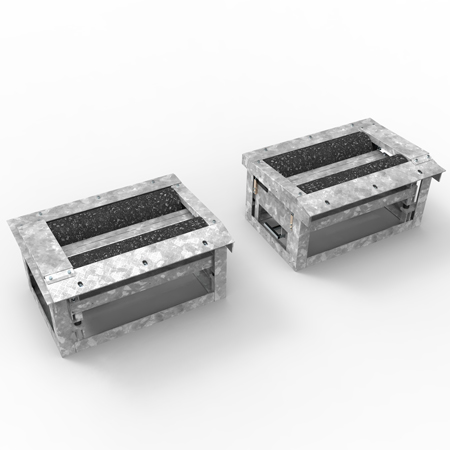

The BM12200 roller brake tester is built to withstand a very high throughput and handle continuous test of full laden axles.

This brake tester features a large range of options that allows for a customized configuration.

OPTIONS

-

- All steel is of highest quality and hot galvanized.

- Consists of an integral motorized gear box, two main rollers and a spring loaded sensor roller, all placed in a galvanized steel frame.

- The wear surfaces of the rollers are based on mesh steel to ensure a long life time and accurate measurements.

Steel mesh plus a flintstone/bauxite surface for test of all tires except spike tires.

Steel mesh for test of all tires including spike tires.

- All gaps are minimized to protect staff.

- Cover plate design around the roller area all have angles to minimize potential tyre damage.

- Can be supplied in a minimum configuration and still allows for later upgrade to all options.

-

- Integrated guide.

- Advanced graphics printout.

- Diagnostic printout with or without connection to PC/Notebook.

- Calculation of test results according to the requirements of many national authorities.

- BM FlexCheck software:

- Advanced data collection, storing and presentation of test results.

- Data capture from a complete inspection lane.

- PDA/smartphone/tablet solution that allows the operator to control and monitor the test results directly on a handheld unit.

BM FlexCheck on smartphone and tablet

-

-

- Integrated guiding system.

- Large analogue dials showing readings of left and right brake forces.

- 65 mm high bright digital readouts of other meaurement results.

- Modularly designed so that it can be customized to existing and future demands.

- Display units are available in daN, kgf or kN.

-

-

-

-

-

-

-

-

The BM12200 roller brake tester is approved by several international authorities i.e. RWTÜV Germany and complies with the ISO standard.